1968

Prestil foundation

Loading color scheme

Prestil foundation

Introduction of the

semi-round concrete post

Introduction of the

round steel post

Ideation and realization

of Tornado steel post

Prestil was founded in 1968 in Friuli, an area rich in hills, mountains and coastal stretches, where the agricultural realities operating in the wine-growing and wine-producing sector are deeply rooted. This allowed us to live the reality of the winemaker in the foreground, understanding and observing with our own eyes the problems he was facing and, consequently, to devise innovative solutions to meet his needs.

In 1988, Prestil revolutionized the production system for pre-stressed concrete poles. The change consisted in pouring the cement directly onto long pre-stressing tracks and introducing a half-round section, totally innovative compared to the solutions available on the market until then. The particular roundness of the pole gives it greater resistance to mechanical stress and reduces the damage that agricultural machinery can suffer during processing.

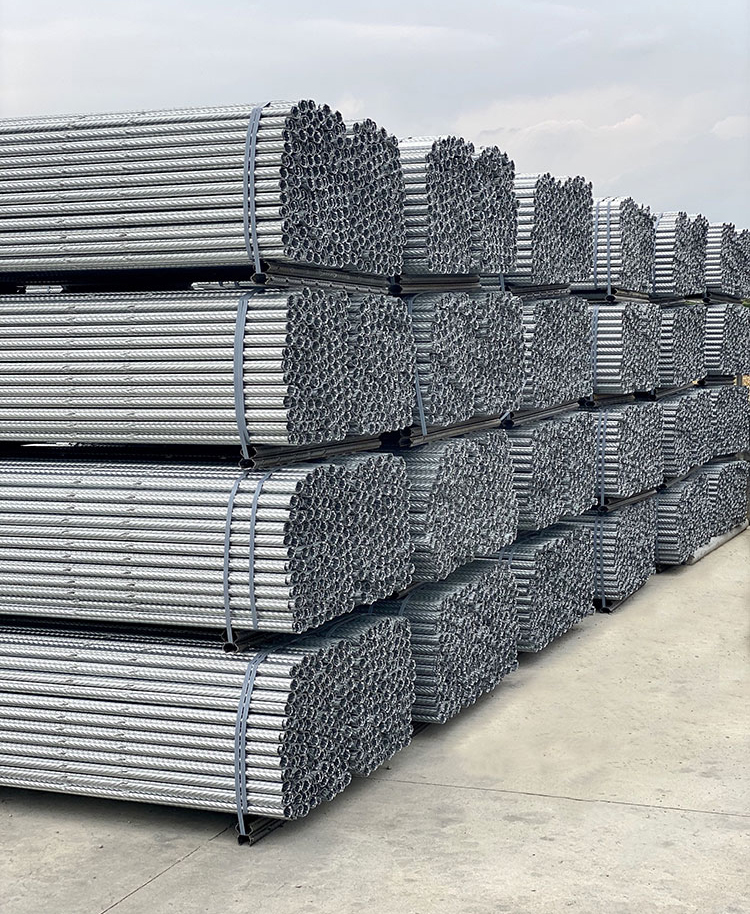

At the end of the 90s, Prestil introduced on the market the steel pole with circular section, which in a short time became one of our leading products. This pole allowed a simpler, quicker and more immediate installing process, guaranteeing, at the same time, the equal technical features of durability and resistance that distinguish concrete, until then used by most winemakers.

Favourite by its geographical position and the ambition that has always characterized us, Prestil has always looked beyond its borders, opening up to new markets constantly.

In 2015, following several years of studies conducted by the technical team of the R&D department and the most respected technicians in the sector, Prestil presented a new metal profiled post: Tornado.

Tornado is characterized by a special patented texture that extends over the entire surface of the post, giving it 30% more resistance than any traditional pole.

The first is the one of the pre-stressed concrete poles, the other for the processing and production of steel and metal poles.

In the production plant for pre-stressed concrete poles, there are as many as 13 tracks that allow us to produce up to 5,000 poles per day.

The metal pole profiling line is fully automated and capable of producing up to 6,000 poles per day.

So that we can make the work of our staff easier and more efficient for deliveries and timely management.

Orders are prepared, checked, packed with care before loading by the logistics staff in order to ensure the best customer service.